SUGAR MILL

Home >SUGAR MILL

SUGAR MILL PHOTO

PRODUCT RANGE : SUGAR MILL SIZE – 16 X 24 TO 60 X 120

CRUSHING CAPACITY : 500 TCD TO 25000 TCD

The performance of a sugar mill crusher is a critical factor in the overall efficiency and productivity of a sugar mill. The crusher is responsible for extracting sugarcane juice from the sugarcane stalks, which is the primary raw material for sugar production. The performance of the crusher directly impacts the quantity and quality of the juice extracted, thus affecting the subsequent sugar production process.

Key factors that influence the performance of a sugar mill crusher include:

- Crushing Efficiency: The crushing efficiency of the crusher refers to the ability to extract maximum juice from the sugarcane stalks. A well-designed and properly adjusted crusher should efficiently crush the sugarcane and extract as much juice as possible.

- Juice Extraction Rate: The juice extraction rate is the percentage of juice extracted from the sugarcane stalks relative to the total weight of the sugarcane. A higher juice extraction rate indicates better performance of the crusher.

- Crushing Capacity: The crushing capacity of the crusher is the quantity of sugarcane that can be processed in a given amount of time. Higher crushing capacity enables the mill to process more sugarcane and increase overall productivity.

- Energy Efficiency: The energy efficiency of the crusher is an important consideration, as it affects the operational costs of the sugar mill. A well-designed and optimized crusher should minimize energy consumption while maintaining high juice extraction rates.

- Maintenance and Downtime: Regular maintenance is essential to keep the crusher in optimal working condition. Minimizing downtime due to maintenance and repairs ensures continuous operation and higher productivity.

- Adjustability: Some crusher models have adjustable settings, allowing operators to control the gap between the crushing rollers. This adjustability helps optimize juice extraction rates based on the type and condition of the sugarcane being processed.

- Durability and Wear Resistance:The crusher components should be made of durable materials that can withstand the abrasive nature of sugarcane and resist wear and tear. High-quality components contribute to the longevity of the crusher and maintain consistent performance.

- Automation and Control Systems: Advanced automation and control systems can enhance the crusher’s performance by optimizing the crushing process, monitoring critical parameters, and ensuring consistent and efficient operation.

To optimize the performance of a sugar mill crusher, it is essential to perform regular maintenance, conduct periodic inspections, and calibrate the crusher settings as needed. Additionally, investing in high-quality crusher equipment and employing advanced technologies can significantly improve overall crusher performance and, consequently, the sugar mill’s efficiency and profitability.

UNLOADER BRIDGE

A cane unloader bridge, also known as a sugar cane unloading bridge or simply a cane unloader, is a critical piece of equipment in sugar mills and sugarcane processing plants. It is used to unload harvested sugarcane from transport vehicles, such as trucks or carts, and transfer it to the sugar mill for further processing.

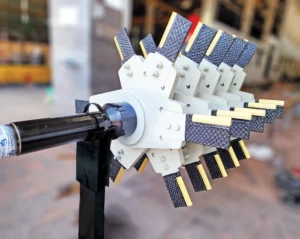

CANE PREPARATORY EQUIPMENT

- Cane Carriers: Cane carriers are conveyors used to transport sugarcane from the cane yard or storage area to the sugar mill. They ensure a continuous and steady flow of sugarcane to the milling process.

- Cane Knives: Cane knives are used to remove the leaves and tops of the sugarcane stalks, known as “trash.” This step is essential to prevent impurities and undesirable material from entering the milling process.

- Cane Choppers: Cane choppers are used to chop or shred the sugarcane stalks into smaller pieces. Chopping the sugarcane increases its surface area, facilitating better extraction of juice during the milling process.

- Cane Mills: While not considered preparatory equipment, cane mills are an integral part of the sugar extraction process. They crush and grind the prepared sugarcane to extract the juice, which is the primary raw material for sugar production.

- Cane Cleaning Equipment: Various cleaning equipment, such as screens and separators, are used to remove dirt, rocks, and other impurities from the sugarcane before it enters the milling process.

Cane Shredders: Cane shredders are heavy-duty machines that shred the chopped sugarcane into finer fibers. The shredded sugarcane is then ready for juice extraction in the milling process.

Cane Levelers: Cane levelers ensure a uniform and consistent flow of sugarcane to the milling process. They help in distributing the cane evenly across the milling rolls, optimizing juice extraction.