ETHANOL

Home >ETHANOL

Ethanol

We provide EPC Ethanol projects Capacities : 30 KLPD to 300 / 500 KLPD

- Harvesting: Sugarcane is a tall, perennial grass cultivated in tropical and subtropical regions. When it reaches maturity, the sugarcane stalks are harvested.

- Milling: After harvesting, the sugarcane stalks are crushed to extract the sugary juice. The juice contains sucrose, which is the main source of fermentable sugars for ethanol production.

- Juice Extraction: The crushed sugarcane is passed through presses or mills to extract the juice from the fibrous material.

- Clarification: The extracted juice often contains impurities, so it is subjected to a clarification process to remove solids and other non-sugar components.

- Evaporation and Concentration: The clarified juice is then concentrated by evaporation to increase the sugar content.

- Fermentation: The concentrated sugarcane juice, known as “sugarcane syrup” or “cane syrup,” is mixed with yeast in fermentation tanks. The yeast consumes the sugars in the syrup and converts them into ethanol and carbon dioxide through the process of fermentation.

- Distillation: After fermentation, the resulting mixture, often referred to as “sugarcane wine” or “cane wine,” contains ethanol along with water and other substances. This mixture is subjected to distillation to separate the ethanol from the other components. Distillation helps increase the ethanol concentration & purity.

- Dehydration: Following distillation, the ethanol is dehydrated to remove any remaining water, resulting in anhydrous ethanol suitable for use as fuel.

Sugarcane ethanol has several advantages as a biofuel:

- It is a renewable resource since sugarcane can be harvested annually.

- Sugarcane contains a high concentration of sucrose, making it an efficient source of fermentable sugars.

- The ethanol production process from sugarcane is well-established and relatively straightforward.

- The production of sugarcane ethanol generates byproducts, such as bagasse (the fibrous residue from sugarcane after juice extraction), which can be used for electricity generation or as feed for animals.

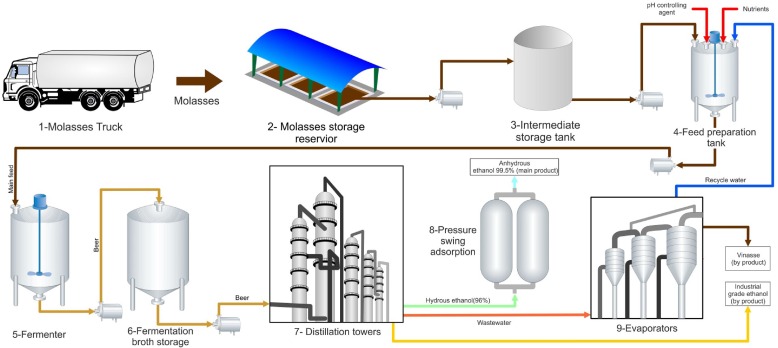

Molasses based ethanol plant

We provide EPC Molasses based Ethanol projects Capacities : 30 KLPD to 300 / 500 KLPD

Molasses-based ethanol plants utilize molasses as the primary feedstock for ethanol production. Molasses is a byproduct of sugar refining, and it is rich in fermentable sugars, primarily sucrose, glucose, and fructose. These sugars can be readily converted into ethanol through fermentation. Molasses-based ethanol production is a common process in regions where sugar production is significant.

The production of ethanol from molasses generally involves the following steps:

- Collection and Preparation of Molasses: Molasses is collected as a byproduct during the sugar extraction process from sugar cane or sugar beets. It is a thick, dark, syrupy liquid that contains residual sugars and other compounds. The collected molasses is then prepared for the fermentation process.

- Dilution: The collected molasses is often diluted with water to achieve the desired concentration of sugars for fermentation..

- Distillation: After fermentation, the resulting mixture, often referred to as “molasses beer,” contains ethanol along with other substances. This mixture is then subjected to distillation to separate the ethanol from the other components. Distillation helps increase the ethanol concentration and purity.

- Dehydration: Following distillation, the ethanol is dehydrated to remove any remaining water, resulting in an anhydrous ethanol product suitable for use as fuel. Molasses-based ethanol production is a valuable process as it utilizes a byproduct from sugar refining, reducing waste and making efficient use of available resources. The ethanol produced from molasses can be blended with gasoline to create ethanol fuel blends, which are commonly used as biofuels in many countries.

Grain-based ethanol plants

We provide EPC Grain based Ethanol projects Capacities : 30 KLPD to 300 / 500 KLPD

Grain-based ethanol plants are facilities that produce ethanol primarily from grains, such as corn (maize)/Rice/Wheat/barley/sorghum. These plants utilize grain as the feedstock for the ethanol production process. Grain-based ethanol is a widely produced biofuel, especially in countries with abundant above grain production.

The production of ethanol from grains generally follows these key steps: (Corn Based)

- Milling: The corn kernels are milled into a fine powder, which increases the surface area and facilitates the subsequent steps of the process.

- Cooking: The milled corn is cooked with water to break down the starch molecules into simpler sugars. This step is essential for the fermentation process.

- Saccharification: Enzymes are added to the cooked corn slurry to further break down the starches into fermentable sugars, mainly glucose.

- Fermentation: The saccharified corn slurry is mixed with yeast, and fermentation occurs. Yeast converts the sugars into ethanol and carbon dioxide. This step produces a mixture called “beer,” which contains ethanol along with some water, yeast, and other substances.

- Distillation: The beer is then distilled to separate the ethanol from the other components. Ethanol has a lower boiling point than water and many other substances present in the beer, making it possible to isolate the ethanol through distillation.

- Dehydration: After distillation, the ethanol is dehydrated to remove any remaining water, increasing its purity and making it suitable for use as fuel.

- Denaturing (optional): Ethanol produced for fuel purposes is often denatured, which means that a small amount of denaturant (usually gasoline or other chemicals) is added to make it unfit for human consumption and avoid alcohol tax.

Grain-based ethanol plants are significant contributors to the biofuel industry, and their output is used to blend with gasoline to create ethanol fuel blends like E10 (10% ethanol and 90% gasoline) or E85 (85% ethanol and 15% gasoline). Ethanol produced from grains helps reduce greenhouse gas emissions and dependence on fossil fuels, making it a valuable component in efforts to promote renewable energy and mitigate climate change.